Substations are an integral and critically important part of any electrical generation, transmission and distribution system which usually located in remote area with harsh environment. With the development of social economy, the inspection work of substation is getting increasingly heavy. Equipment inspection and repair is an important work of substation duty. However, due to the large number and the high density of the equipments in the substaion, it takes more than 2 hours to finish one manual inspection of a large station. Also, manual inspection is very easy to lead to omissions of inspection work, lack of technical supervision means, slow transmission of inspection information and standard inspection process can not be effectively implemented, etc..

At present, substation equipment inspection mainly relies on manual inspection. Due to the constraints of climate conditions, environmental factors and personnel quality, the quality of inspection can not be guaranteed. At the same time, manual inspection can not timely feed back the information of equipment running status and defects. The traditional inspection management method is also difficult to effectively supervise the inspection personnel, easily resulting in equipment accidents caused by the neglect of duty of the inspection personnel.

Therefore, in order to ensure the smooth conduct of line and equipment inspection and reduce unnecessary economic losses, the call for reforming the traditional backward inspection method is getting higher and higher. How to supervise the inspection personnel‘s performance and standardize inspection work management has become a common concern and urgent problem for power grid managers.

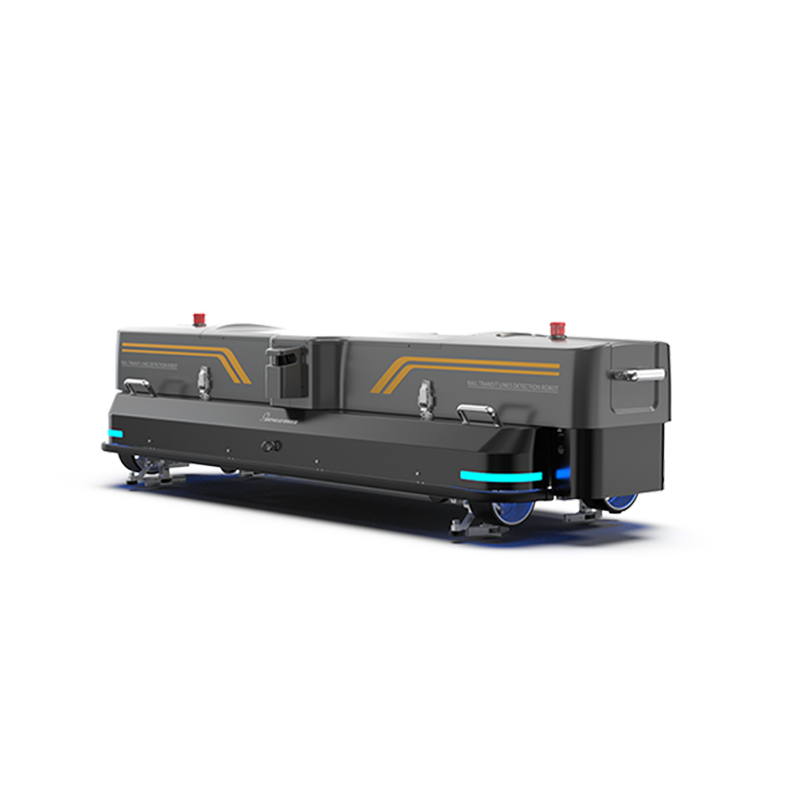

The intelligent substation inspection robot independently developed by Shenhao can replace manpower to realize remote routine inspection, which greatly improves efficiency and frequency of operation and maintenance while reducing manual work, changes the traditional operation and maintenance mode, and realizes intelligent operation and maintenance. It uses meter intelligent recognition, infrared temperature measurement, high-definition image recognition, partial discharge detection, gas leakage monitoring, noise pickup and analysis, environmental temperature and humidity, and other functional modules to achieve full coverage monitoring of equipment status in various power scenarios.

Hangzhou Shenhao Technology Co., Ltd. is located in Hangzhou, Zhejiang Province, China. As one of the leading robot manufacturers and developers in China, we are committed to providing customers with professional robotic solutions in the field of smart robotic inspection in power grid, oil and gas chemical industry, rail transportation and other industries.