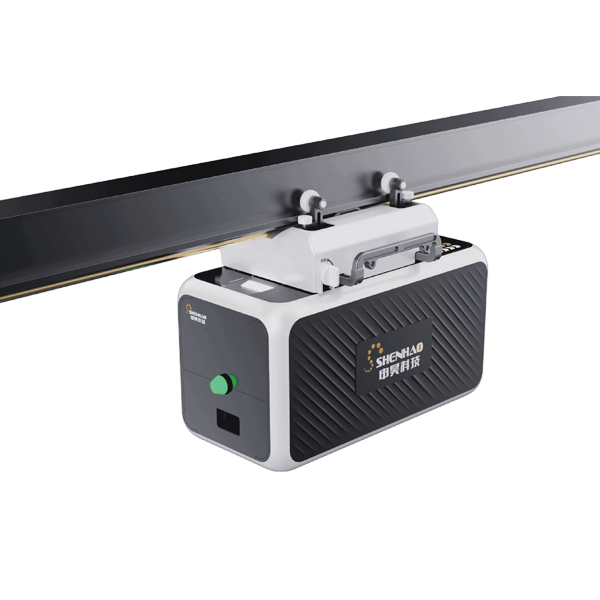

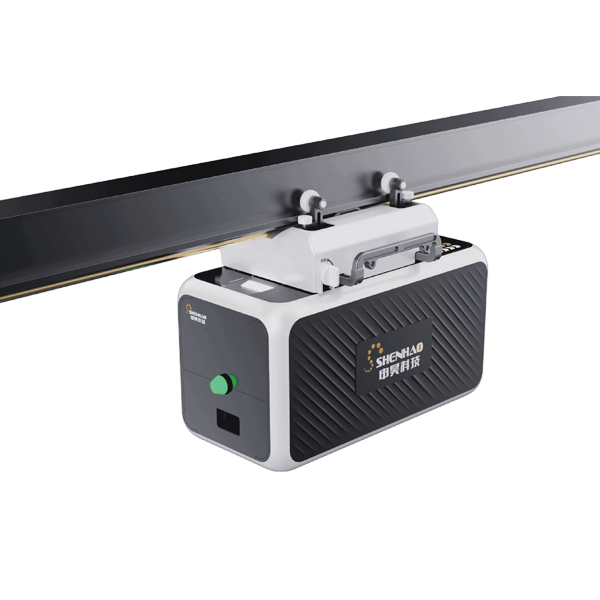

TECHNICAL PARAMETERS

Size

500*250*300mm

Moving Mode

Autonomous operating

Battery Life

2h(one battery)

Charging Time

1.5h

Working Temperature

-10℃~40℃

Waterproof and Dustproof

IP43

Catenary Intelligent Inspection Robot

Load ng

Mileage positioning

Export report

Remote operation

Rapid entry and derailment

Contact line surface defect inspection

Contact wire abrasion measurement

Size

Moving Mode

Battery Life

Charging Time

Working Temperature

Waterproof and Dustproof

2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。